Ever wonder what goes into t-shirt printing? The journey from changing a plain t-shirt into a shirt that speaks to your personality is simple. You can change the printing method to suit your personal and professional needs.

Some of the most popular ways to print on t-shirts include screen printing, direct-to-garment printing, dye-sublimation, heat press printing, and heat transferable vinyls. While these are the methods that dominate the industry, you’ll find a few other ways to print an image onto a shirt.

The designs you choose to print will differ according to your brand and what your customers want. Because of the many different options for printing t-shirts, you’ll need to decide which t-shirt printing from home technique that best fits your brand and target market.

8 Best T-Shirt Printing Techniques

Different t-shirt printing techniques have different levels of efficacy.

One method may work if you’re a small-scale business that prints ten t-shirts per day but won’t be as effective when you’re printing a hundred shirts a day.

The method you choose will also vary depending on the material you choose to print on and the number of colors you want to print.

Some methods allow multiple colors to be printed, while others only allow one color.

You also want to consider the initial investment of acquiring the printing equipment.

With that said, let’s look at the top 9 methods for printing t-shirts.

1. Screen Printing

Screen printing is a technique where the mesh is used to transfer ink onto a shirt, except in areas where it’s made impermeable to the ink by a blocking stencil.

Screen printing is also known as serigraphy.

It’s also one of the methods the professional material printers prefer due to the high-quality nature of the end product.

You’ll find that natural fibers, like cotton, behave the best when printed on due to how rapidly they absorb the ink.

How To Screen Print On T-Shirts

You’ll need a synthetic thread, like nylon mesh, and a template to print from to do screen printing.

The nylon mesh of the screen holds the stencil in place, and a waterproof martial blocks the negative space.

You then spread the ink over the screen using a squeegee. The blocked-off negative space allows the print to be transferred to the t-shirt.

With some curing time, you have yourself a professionally printed shirt — one that bears your unique design!

Why Choose Silkscreen Printing?

Silkscreen printing is one of the best and oldest methods of printing t-shirts and has remained a popular option as it leaves behind a long-lasting and vibrant design.

This printing method allows for multicolored designs; you just have to create different screens for each new color you add to the print.

It seems like a time-consuming method but creates the least amount of waste, as you reuse the same screens and template more than once.

Because you create multiple screens, you can efficiently sustain large order quantities.

If your design requires more than 4-6 colors and you don’t see yourself making all the individual screens, silkscreen printing may not be the best option for you.

Pros Of Using Screen Printing

- Relatively cost-efficient for producing bulk orders.

- The ink absorbs deep into the garment, leaving saturated and stunning designs.

- Silkscreens can be reused, making the method time-efficient and eco-friendly.

- Compatible with most fabrics (works best on natural fibers).

- The designs are durable.

Cons Of Using Screen Printing

- The inks used for screen printing make the method a bit messy.

- It’s not suited for complex, multi-color designs because a new screen has to be created for each color.

- Requires practice to master.

- It needs to be stored in a large, dust-free area to ensure longevity.

How Much Does It Cost To Start Screen printing?

This post goes into detail about everything you need to know about screen printing and the exact equipment you’ll need to get started.

They estimate a price of between $1,030 to $3,618 to get your screen printing business started.

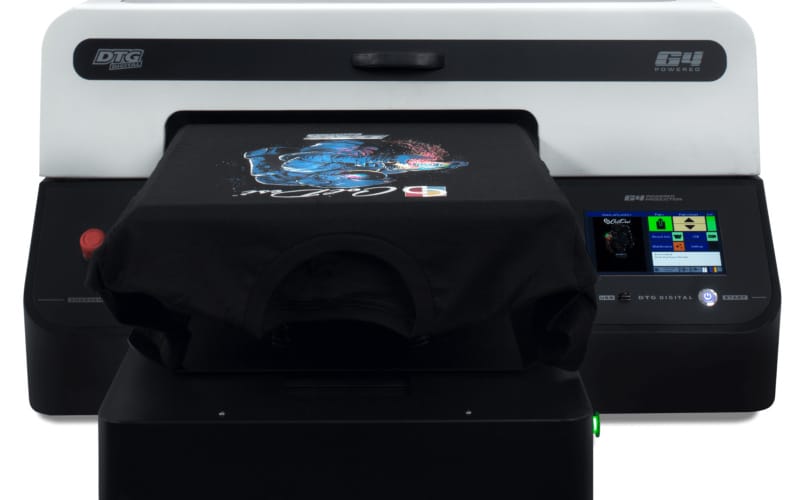

2. Direct To Garments (DTG)

Direct to Garment Printing (DTG) is also called ink-jet to garment printing and is the process of printing graphics onto textiles.

It uses ink-jet technology to print any image onto a t-shirt — so essentially a t-shirt printer.

DTG printing is different from silkscreen printing because you can print anything you want onto your t-shirt.

Some DTG printers can print up to 16 million different colors in one single pass — versus the multiple passes you have to make with a silkscreen.

The printer’s ink soaks into the garment itself rather than resting atop as iron-on transfers would.

If you choose to go DTG, you want to invest in a good quality printer. Poor-quality printers are likely to leave you with a lot of maintenance issues and low-quality production.

Note: I invested in my own machine a few years ago when DTG was just a few years on the market. The machine was just under $10k and the company even sent out a rep to train me. But at the end of the day, I realized I wasn’t prepared to print the amount of shirts per day to run a machine like that, so I sold the DTG printer.

Where sellers can really benefit from DTG is Print-on-demand. This way, you don’t have to worry about the maintenance or headaches, but can benefit from being able to do one-off prints.

How To DTG Print On T-Shirts

If you have the DTG printer, the process is easy.

Get a design ready on your computer. Assemble the correct inks for your printer. Print and allow the ink to dry.

It’s as simple as that.

Why Choose DTG Printing?

If you’re printing overly complex designs, DTG printing is the option for you. The printer will define even the smallest details while printing the design to the tee accurately.

DTG printing says goodbye to the days of thick layers left on your t-shirt.

Pros Of Using Direct To Garments

- Can print the most complicated multi-color designs.

- Super-fast printing makes it suitable for large orders.

- The compact printer saves you space.

- Minimal ink spilling.

- Soft and smooth prints.

Cons Of Using Direct To Garments

- Only suitable for printing on cotton t-shirts (printing on other materials will make the design dull).

- DTG printers are an investment, making them unaffordable for those starting out or with small budgets.

- The printer will require maintenance, which can also rack up money.

- While technology has gotten much better, the white inks are still a maintenance issue in many machines.

How Much Does It Cost To Start DTG Printing?

Creating your own DTG setup is costly.

DTG printing will cost you a minimum of $12,500 to $25,000 for a complete and professional setup.

The most expensive DTG printing setups can easily exceed $250,000, making this a much more costly way of printing than silkscreen printing.

3. Dye Sublimation

If you’ve ever seen a t-shirt covered entirely by one design, you most likely saw a t-shirt that was printed on using dye sublimation.

This printing method doesn’t work on cotton or natural fabrics but leaves behind a high-resolution print on polyester t-shirts.

If you’re using dye sublimation as your printing technique, you’re using a liquid dye that solidifies when it comes into contact with polyester.

For this process to work effectively, you have to apply both heat and pressure.

How Dye Sublimation Works

This process works by using the science of sublimation.

Heat and pressure are applied to a solid, turning it into a gas without passing through the liquid phase (an endothermic reaction).

The desired design is printed onto a transfer paper, which is fed through a high-pressure roller heat-press, turning the ink in the paper into a gas.

The polymer molecules of the polyester soften under the heat, allowing the gas to penetrate the fibers that close up when combined with the ink — effectively sealing in the design.

Why Choose Dye Sublimation Printing?

What makes dye sublimation an excellent option for printing is that it leaves a durable and high-quality design on your t-shirt.

You can also mass-produce t-shirts using this method, making it time effective once you have the tools.

Pros Of Using Dye Sublimation

- Super soft and smooth designs that don’t fade over time.

- Great for printing on synthetic materials like polyester — the higher the polyester quantity, the better the print.

- Produces quality prints that won’t fade, peel, crack, or deteriorate in other ways.

Cons Of Using Dye Sublimation

- Relatively expensive to set up.

- An unsuitable method to print on natural textiles.

- Creases and folds are difficult to print on.

How Much Does It Cost To Start Dye Sublimation Printing?

If you have a sum of money waiting around, you’re in luck!

Sublimation printing has one of the lowest production costs with high-profit margins.

To set up your dye-sublimation printer will cost you around $1,500, depending on the printer and materials you select.

4. Heat Press Printing | Inkjet Printer

If you’re a newbie to the t-shirt printing industry and you don’t have many orders to fulfill, heat press printing is an excellent option for you!

Why? Well, because it saves you resources and time.

One method of heat press printing requires a printer and transfer paper. Another method of heat press printing requires a vinyl cutting machine. Each method requires a heat press.

Either way, you can have any design you want on your t-shirt if you have a digital copy of the image.

How To Heat Press Print

Print your desired design onto the paper using your ink-jet printer and transfer paper.

Transfer paper is a piece of paper coated in wax and pigments. You can use an ink-jet printer to print the image on the transfer paper and then heat press the image onto your shirt.

Press the design onto the shirt using a heat press. The heat of the press will activate the adhesive material on one side, adhering the design to the shirt, while the other side will have a removable, glossy tape.

It’s always a good idea to check the transfer paper’s instructions to see how long you should press

it for, as well as at which temperature.

Why Choose Heat Press Printing?

Heat press printing is an easy technique most can do at home. Some transfer papers simply require the heat of an iron to transfer the image to the t-shirt.

It’s also a really affordable option on the t-shirt printing market — but much like the other methods, it can get expensive once you look at specialized equipment.

Pros Of Using Heat Press Printing

- Relatively simple to set up and use.

- Produces visually stunning full-color prints.

- Suitable for complex designs.

Cons Of Using Heat Press Printing

- Not the best option for dark t-shirts.

- Unsuitable for heat-sensitive fabrics.

- Slower than most other methods.

How Much Does It Cost To Start Heat Press Printing?

Heat press printing can be one of the cheapest options available, depending on the equipment you choose to buy.

Generally, you’ll find that professional equipment can range from $300 to upwards of $3,000.

The low initial investment makes heat press printing an excellent option for those looking into t-shirt printing.

5. Heat Transfer Vinyl

Heat transfer vinyl comes in various shapes, colors, and patterns. It requires you to cut it into different shapes before transferring it to a t-shirt using a heat press.

The heat press can either be a specialized machine or a simple iron. I prefer a clamshell heat press over an iron every time, especially if you plan to do a good number of shirts.

To cut out the vinyl shapes, you’ll need a specialized die-cutting machine — the one most used by home designers is the Cricut machine.

If you want to create tiny graphics or slogans for t-shirts, this technique will give you good quality results.

How To Print With Heat Transfer Vinyl

There are a few simple steps to transfer your design to a t-shirt using heat transfer vinyl.

Start by preparing your cut file on your computer and send it to your machine.

After cutting, weed (remove) any parts that don’t belong in the design. For example, if you’re cutting a butterfly, remove the negative space you don’t want to transfer.

Then, simply apply the design using a heat press, remove the glossy sheet from the t-shirt from corner to corner (slowly), and you’re done!

Why Choose Heat Transfer Vinyl Printing?

Heat transfer vinyl is a great entry-level way to get started with designing t-shirts.

It usually comes in a roll and has an adhesive backing — this makes it easy to cut, weed, and place the design on a t-shirt for heat application.

The simple process makes it easy for many beginners to master in a few attempts (if not the first!).

It’s also a cheap way to customize t-shirts on a small scale or for occasional gifts.

Pros Of Using Transfer Vinyl Printing

- Produces long-lasting results that look good.

- The designs are easily adjustable.

- Easy to do for people of almost all ages.

Cons Of Using Transfer Vinyl Printing

- Not suitable for huge orders.

- Not suited for heat-sensitive fabrics.

- Not suited for complex designs or 3+ color designs.

How Much Does It Cost To Start Transfer Vinyl Printing?

Starting your heat transferable vinyl business will cost you $200 to $700.

If you buy a Cricut machine, you’ll also be able to cut much more than just heat transferable vinyl designs.

The low price tag of vinyl transfers makes it accessible to most people who are just starting out or simply want to customize t-shirts on the side.

Other Ways You Can Print On T-Shirts

While the options above cover the most common ways you can add designs to t-shirts, there are a few other ways you can also achieve this.

7. Plastisol Transfer

Like screen printing, plastisol transfer uses screens to imprint an image onto a t-shirt. The difference? You transfer the dye to the plastisol and then to the t-shirt.

Often the designs are sent to a printing company that prints the design onto plastisol and shipped back to the designer.

The huge advantage to this method is that you can simply order the transfers, say 100 at a time. Then you can heat press them to the shirts as the orders come in. This prevents pre-printing a set number and size of t-shirts before you sell them.

8. Stencil Printing

Stencil printing is mainly used in recreational circumstances where the individual uses fabric paint or ink to create a design on a t-shirt.

Using stencils makes it a cheap option for those who only want to customize a t-shirt for special occasions.

It can be difficult for some because stencil options can be pretty limited, and the process is quite time-consuming.

9. Tie Dyeing

Tie-dyeing is a method that has made a huge comeback.

The only disadvantage to tie-dye is that you have little control over the design. But there are ways to apply a material to the shirt where you can control the design.

Using Batik (a method of dyeing where you apply wax to the parts you don’t want the dye to penetrate) or tie-dye, you can easily create handmade designs.

This method is time-consuming but works really well if you want to add various patterns or images to a t-shirt.

Conclusion

T-shirt printing can be a lucrative business, especially if you create unique designs or print your own art onto the shirts.

There are various ways you can print designs onto t-shirts, and the method you use depends entirely on your demand and preferred printing method.

The prices also vary greatly and provide an easy way for anyone to get into the business of t-shirt printing — even if it’s just for fun!

My favorite methods are DTG printing (via Print-on-demand) and Heat Transfer Vinyl printing. These two methods are extremely low-cost to get started and have been proven to be very profitable over the years.

Bryan E. Robinson is the former owner of TshirtGrowth. He has sold t-shirts since 2006 through dropshipping, screen printing, vinyl printing, DTG, Print on Demand, and more. Bryan has created his own t-shirt designs through Photoshop, Canva, and other platforms, as well as worked with freelancers to create many of his designs. Besides t-shirts, Bryan has over 18 years of experience in online marketing with eCommerce, B2B SaaS, B2C products, and more.