Dye sublimation versus screen printing: What are the differences, and how do you know which one is best for you and your business?

There are several factors to take into consideration when comparing dye sublimation versus screen printing. These factors include the process of the printing technique, the consistency of your designs, color, volume, printable surfaces, and the durability of your design after printing.

What are the main differences between Screen Printing and Dye Sublimation?

The main differences between screen printing and dye sublimation are the types of fabrics that can be printed(screen print can be printed on most fabrics; sublimation is mostly printed on polyester), the quality and number of colors with each method (screen print uses fewer colors and are not as vivid as sublimation), and the process used to print (screen print is brushed onto the shirt, while sublimation is created using a printing system that transfers dye to the shirt).

Our short guide will help to outline the biggest differences between dye sublimation and screen printing and will help you to decide on which one to choose to meet your businesses’ goals.

Dye Sublimation Vs. Screen Printing: Process

Screen printing is the process of ‘printing’ your designs onto t-shirts or textiles using specific inks and a mesh or silkscreen. The screen is usually prepped with a stencil before you begin printing, and you can apply the ink to the backside of the screen to transfer your image onto your product.

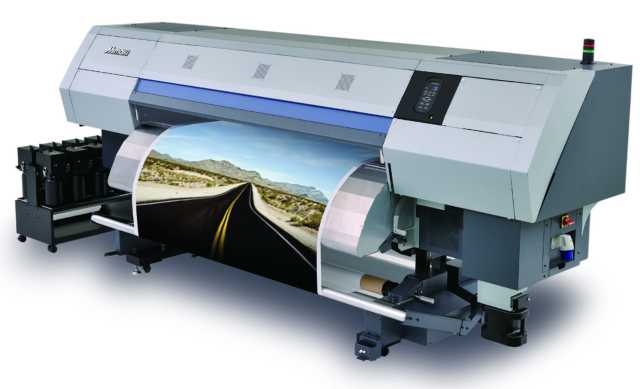

Dye sublimation works by printing out your design or image onto sublimation paper. You can then transfer or print your design onto your product using a heat press.

Screen printing will work best for small businesses that don’t necessarily have the money to buy more expensive tools. Screen printing materials are relatively inexpensive and require no machinery to get started.

Dye sublimation is a good pick for small businesses that have the cash to invest in more expensive t-shirt printing equipment.

Dye Sublimation Vs. Screen Printing: Designs

While both dye sublimation and screen printing offer high-quality t-shirt printing methods, there is a slight difference in what kind of designs each technique can achieve.

Dye sublimation is much easier to master than screen printing. Once your design or graphic has been finalized, you can print your image directly onto sublimation paper using a sublimation printer. Then you will need to use a heat press to transfer your design from the paper to your t-shirt.

Because your design is much easier to produce, dye sublimation produces more consistent design quality and creates more complex designs.

On the other hand, screen printing designs take much longer to complete, and your designs may be slightly more inconsistent. This is because you will need to add each layer and any additional colors to your design one by one. Because it is all done by hand, it is much more difficult to achieve the same image time and time again.

With practice and patience, some screen printers may achieve more complex designs. You can also use other types of inks – such as glitter, iridescent, or 3D-effect inks – to create more interesting designs.

Dye sublimation is best for more complicated designs, while screen printing is better for more simple designs. With the right technique and extra time, however, you can also achieve complex designs with screen printing.

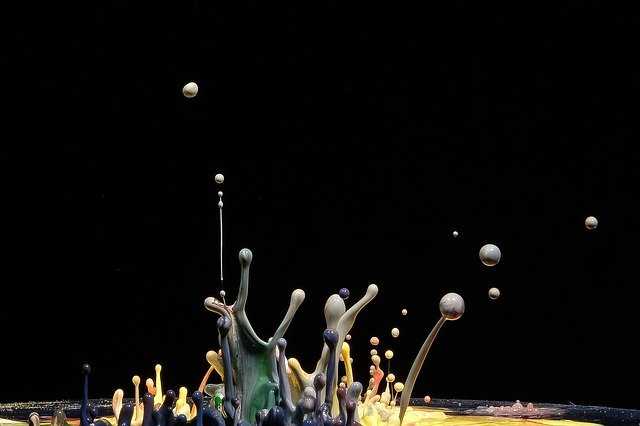

Dye Sublimation Vs. Screen Printing: Color

The screen printing process is more complex than sublimation printing, and you will need to add each color in your design using a new silkscreen. Constantly changing screens can not only be time-consuming but can increase your margin for error, as well.

Dye sublimation allows you to print several colors at once and lets you add more color combinations into your design without any extra work.

Sublimation printing is better for more colorful and complicated designs. But, if your designs are simple and you only need to use a handful of colors, then the screen printing method may be right for you.

Dye Sublimation Vs. Screen Printing: Volume

Dye sublimation is a faster printing technique because your completed designs are transferred directly onto your shirt. It will take more time to complete larger batches, though, because you will still need to use your heat press to apply your designs.

Screen Printing is great for making more t-shirts at a time. While the initial setup of the equipment may take some time, it is easy to repeat the process on several shirts when the equipment is ready.

Because of this, screen printing is better for small businesses looking to create larger batches of more simple designs. Dye sublimation is a better fit for a business that wants to print its products on-demand or print a small number of t-shirts with a more complicated design.

Dye Sublimation Vs. Screen Printing: Surfaces

Dye sublimation is best used on polyester t-shirts or other fabrics and surfaces coated with a polymer, like some plastic products. The products or fabric need to be light in color, as dye sublimation works best on a white background.

Screen printing can be used on various surfaces with the right ink. Small t-shirt businesses will have much more variety when choosing their material because screen printing works well on cotton, polyester, cotton blends, and even latex. You can also use screen printing for wood, glass, plastic, and ceramics.

If your small business focuses on exclusively printing t-shirts, then dye sublimation is a fantastic choice. But, if you want to grow and expand your business into other products, then you may be better suited to screen printing.

Dye Sublimation Vs. Screen Printing: Durability

Dye sublimation and screen printing are comparable when it comes to durability. Screen printing uses specialized inks to print the design onto the product, allowing the ink to bind with the material of the product.

This gives the product a smooth surface with a durable print. While the print may fade slightly over time, it shouldn’t chip or crack. These problems only occur if you are using low-quality inks.

Dye sublimation is just as – if not more – durable than screen printing. When you transfer your design from the paper to your product using a heat press, the heat helps the dye particles to bond with the product’s material.

This helps to keep your design looking brand new and prevents it from fading or cracking.

When it comes to the durability of screen printing and dye sublimation, you will have long-lasting results and fantastic products no matter which method you choose.

Conclusion

So, which printing method will work best for you? Well, that all depends on the goals of your business.

If you want to print small product batches that have colorful or complex designs, and you have the money to cover the cost of the equipment, then dye sublimation is for you.

But, if you want to create a bigger number of products with more simplistic designs in a few select colors, and you want a cheaper start-up option, then you’ll have much more success with screen printing.

Bryan E. Robinson is the former owner of TshirtGrowth. He has sold t-shirts since 2006 through dropshipping, screen printing, vinyl printing, DTG, Print on Demand, and more. Bryan has created his own t-shirt designs through Photoshop, Canva, and other platforms, as well as worked with freelancers to create many of his designs. Besides t-shirts, Bryan has over 18 years of experience in online marketing with eCommerce, B2B SaaS, B2C products, and more.