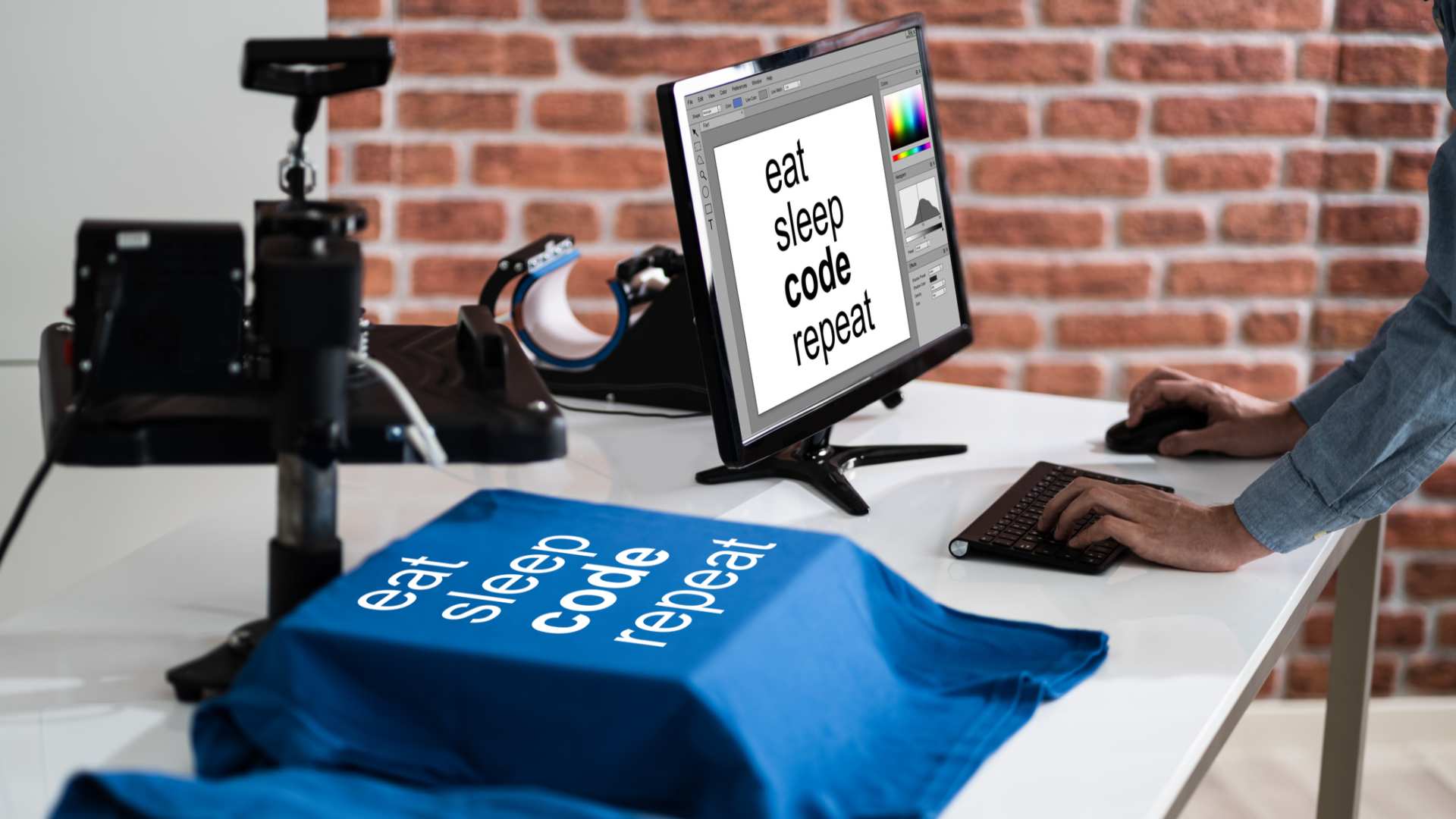

So, you’re starting up your own t-shirt printing business and branching out into the world of entrepreneurship. But now you need to decide on a printing technique: vinyl t-shirt printing or screen printing. If you’re unsure which printing method is best for you, look no further!

The main differences between vinyl t-shirt printing and screen printing are the equipment you will need, the printing process or technique, the types of surfaces you will be able to print on, time, volume, and the overall texture of the final product.

Our quick and comprehensive guide on the differences between vinyl and screen printing will help you on the road to success.

Vinyl Vs. Screen Printing: Equipment

The first thing you’ll need to know about either of these printing methods is what you’ll need to get started.

Screen Printing Supplies

Screen Printing usually requires more supplies, but they are relatively inexpensive to buy and can be easily sourced online. These supplies include your mesh screen, a stencil to lay over the screen, a squeegee, fabric or screen printing ink, and a heat source to permanently set your design.

The stencils you will use to lay over your mesh screen are generally made from adhesive vinyl, which is more affordable than heat-transfer vinyl. Heat-transfer vinyl (HTV) is used to create vinyl t-shirts.

Heat Transfer Vinyl Supplies

Heat-transfer vinyl requires fewer supplies, but some equipment can be expensive. These supplies include a vinyl cutter, weeding tool, and a heat source to adhere the vinyl onto the shirt. You will also need to buy heat-transfer vinyl sheets to make your designs.

The weeding tool is used to remove your design from the cut image and pull it away from the negative space around your design. While using a heat press is advantageous to helping your design be more durable, you can also use other heat sources to adhere the vinyl, like an iron or heat gun.

While the initial equipment for HTV is more expensive, you will only need to replace your consumables. In this case, your only consumable is the sheet of vinyl. This can become expensive when making a larger batch of t-shirts.

Vinyl Vs. Screen Printing: Process

The screen printing process is relatively straightforward and has a small learning curve for beginners. To transfer your design to your shirt using the screen printing method, you will need to use a mesh screen layered with a pre-cut stencil or design.

Then, you will place the screen over your desired design area on your shirt. Using fabric or screen printing ink and a squeegee, you can layer the ink onto your shirt by pulling it across the screen.

For multiple colors or more than one design element, you may have to have multiple screens to achieve your desired image.

When creating printed t-shirts using vinyl, you will need to print your desired design out using a die-cutting machine. You can then remove your design from the vinyl sheet using your weeding tool. The design is then placed directly onto the shirt and adhered using a heat source.

Vinyl Vs. Screen Printing: Surfaces

While vinyl and screen printing can be used for cotton or polyester t-shirts, screen printing is versatile. This is because screen printing can be used on textured fabrics. HTV needs to be pressed onto a flat surface to avoid having the design peel, chip or crack.

Screen printing can also be used on other textiles, such as acrylic, wood, and paper. You can achieve this by using acrylic screen printing ink.

Vinyl Vs. Screen Printing: Time

Vinyl t-shirt printing is much quicker than screen printing. Once the design has adhered to your shirt, it is ready to be worn. Although you cannot wash the shirt for twenty-four hours after the vinyl application, you can wear it within a few minutes of printing.

Screen printing has a much lengthier process. The project time takes much longer because you will need to apply each layer of ink individually, including different design elements and additional colors.

Once you have finished the screen printing process, the shirt will need to rest until the ink is completely dry. This may require time and patience, especially if you have several ink layers.

Vinyl Vs. Screen Printing: Volume

When running a small business, the number of products you can produce can make a huge difference. If you are running a small t-shirt printing business, the number of shirts you will need to make will depend on your business model and your demand.

Vinyl t-shirt printing is best for a small number of shirts. This is because HTV is expensive, and you will need to print each design out before adhering it to the shirt. You can, however, create a small batch of shirts with different designs.

Screen printing is best for bigger batches of shirts. It can be time-consuming to set up the mesh screens for printing. But, if you are going to print multiple shirts of the same design, then screen printing will be the best choice.

Vinyl Vs. Screen Printing: Texture

One of the most important aspects of t-shirt printing is producing a product that customers will love. But it isn’t enough to have an amazing design. The overall feel of the shirt can be just important as the design and can influence a customer’s decision on whether or not to purchase your apparel.

Vinyl t-shirts often create a more rigid, textured feel when the HTV designs are applied. While this may not change the overall comfort of the shirt when you are printing with a smaller design, a large design that covers the front of the shirt may end up feeling uncomfortable against your skin.

Screen-printed t-shirts are generally much softer than vinyl. This is because the ink soaks into and binds with the shirt’s fabric. While you may feel a slight texture difference between the ink and the fabric, the difference is not often felt when the shirt is being worn.

Two Great T-shirt Printing Techniques

Both screen printing and vinyl t-shirt printing are great methods for starting up a small t-shirt printing business. While the method you use depends on what is best for you and your business, we hope our guide has helped to outline the difference between the two techniques.

Bryan E. Robinson is the former owner of TshirtGrowth. He has sold t-shirts since 2006 through dropshipping, screen printing, vinyl printing, DTG, Print on Demand, and more. Bryan has created his own t-shirt designs through Photoshop, Canva, and other platforms, as well as worked with freelancers to create many of his designs. Besides t-shirts, Bryan has over 18 years of experience in online marketing with eCommerce, B2B SaaS, B2C products, and more.